Lifting in Windy Conditions

Wind is an underestimated factor in mobile crane accidents. Whether operating a 34’ bucket van or a 55-ton crane with a 151’ boom and a jib, wind affects how your load will behave and, therefore, how you must operate your equipment. It is imperative to consult your operator’s manual for model-specific guidelines, but below are a few factors to observe when operating in windy conditions.

What is wind? Wind is created by air moving through different temperatures and atmospheric pressures seeking equilibrium. Simply put, wind is air in motion. Before starting a job, be sure to have the following information: the weight of the load, max projected surface area of load, the current wind speed, and the calculated maximum permissible wind speed from your crane’s load chart book.

- Load Weight: The heavier the load, the greater the downward force, and the less susceptible the load is to the wind force.

- Load Surface Area: The larger the surface area of your load, the greater the resistance between object and wind, and therefore the more responsive the load is to wind. Similar to a sail on a boat, a larger surface area will be pushed more easily by the wind.

- Current Wind Speed: Wind speed is the movement of air at a particular distance over a period of time. This can be expressed as meters per second, knots (nautical mile per hour), miles per hour, and feet per second. In order to know the current wind speed, you will want to consult a wind reporting/forecasting service like windfinder.com or use an anemometer.

Other factors to consider when calculating the impact of wind are location, terrain, and lift height.

- Location: When assessing the location of a project, consider the proximity of hazards such as power lines. Since power lines can swing in the wind, it is important to calculate extra distance from the crane load to reduce the chance of collision.

- Terrain: Air flow is slowed by friction as it interacts with the terrain on earth. Rough terrain, like a wooded area, will cause more friction with air flows and slow the speed of the wind. Alternately, smooth terrain, like a body of water offers little resistance to air and thus little friction to slow the speed of the wind. Observing the terrain roughness of your work area can help you anticipate how much the wind may affect your worksite. Additionally, the complexities of certain terrains will affect wind. For example, urban environments have the potential for urban canyons, which are areas located between high-rise buildings. Depending on the direction of the wind that day, air in these spaces may experience a funnel effect and pick up speed.

- Height: When considering height, know that wind speed increases the further air flow is from the ground since winds at lower atmospheric layers are reduced by ground friction. This means that air 600’ above ground will move at a slightly different speed than air 30’ above ground. Take this into account when you use a wind forecasting service (which may take wind measurements at very high heights) and when considering the height of your lift.

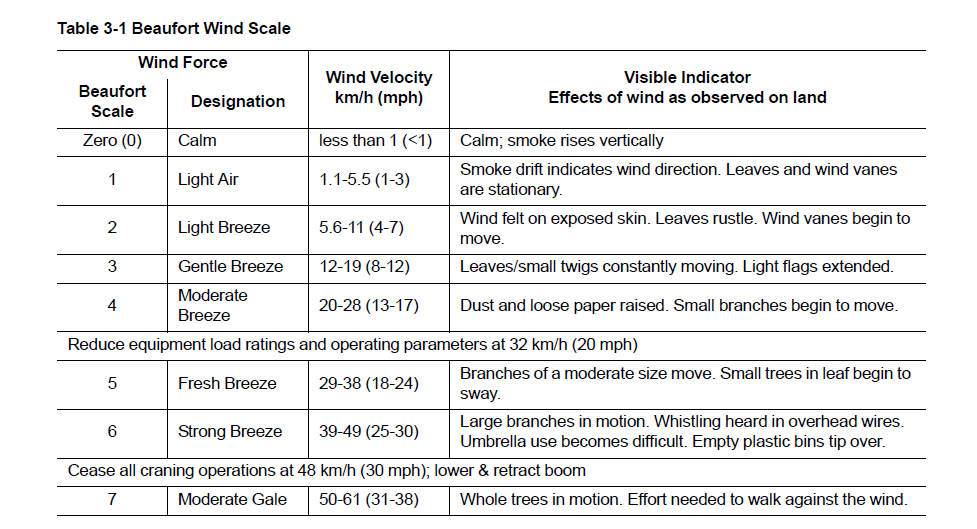

Your operator’s manual might use a Beaufort wind scale chart to show wind speed ranges and their relative safety. The Beaufort scale includes subjective environmental conditions as well as measurable wind speed ranges in its rankings. This allows operators to use both environmental indicators (e.g. branches of moderate size are moving) and instrument measurements (e.g. anemometer reading of 19) to make informed safety decisions. However, because wind speed is the primary indicator on the Beaufort scale, if your current wind speed is above the permissible limit for your machine, it is unsafe to continue operations and work should be discontinued until conditions improve. Some operator’s manuals may include wind limitations as a line on the crane's load charts, with the permissible wind speed being dependent on lift height and weight. In either case, follow the guidance offered in the operator’s manual to determine whether wind conditions are safe.

While wind can impact work conditions, staying aware of load dimensions, environmental factors, and your equipment’s limitations will allow you to make safe decisions for your team.